Diesel Emission Control Systems Tier 4 and Tier 5: Advancing Towards Significant Pollution Reduction

Les moteurs diesel sont connus comme une source importante d'émissions polluantes, notamment les oxydes d'azote (NOx) et les particules fines (PM). Pour réduire ces émissions, les réglementations environnementales ont évolué au fil des ans, conduisant à la mise en place de normes de plus en plus strictes par les États-Unis et l'Union européenne. Les systèmes antipollution diesel Tier 4 et Tier 5 sont les dernières étapes de cette évolution. La norme Tier 4, introduite en 2008, vise à réduire les émissions de NOx et de PM et la norme Tier 5, qui devrait entrer en vigueur en 2025, prévoit des réductions encore plus importantes des émissions.

Normes Tier 4

The Tier 4 regulations were introduced by the Environmental Protection Agency (EPA) in the United States. These standards target a significant reduction in particulate matter (PM), nitrogen oxides (NOx), and non-methane hydrocarbons (NMHC) emitted by diesel engines.

Key aspects of Tier 4 standards include:

90% reduction in PM emissions compared to Tier 3 standards introduced in 2002.

45% reduction in NOx emissions compared to Tier 3.

70% reduction in NMHC emissions compared to Tier 3.

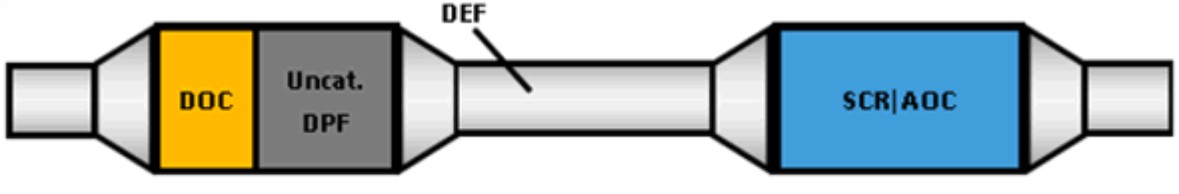

To comply with Tier 4 standards, diesel engine manufacturers have developed various technologies. Tier 4 systems utilize a combination of these technologies to minimize air pollutant emissions. Here are the primary components and their functions:

Diesel Particulate Filters (DPF)

The DPF is a filter that captures fine particulate matter (PM) emitted by diesel engines.

Typically made of ceramic or metal, the filter is designed to trap particles as small as 10 micrometers.

A regeneration process is required to remove accumulated particles and maintain efficiency.

Selective Catalytic Reduction (SCR) Systems

SCR systems use a catalyst to reduce NOx emissions.

The catalyst, often made of vanadium or tungsten, reacts with NOx to convert it into nitrogen (N₂) and water (H₂O).

The SCR process requires the injection of diesel exhaust fluid (DEF) (urea solution) to enhance NOx reduction in the catalyst.

High-Pressure Fuel Injection Systems

These systems use fuel injection pumps to deliver diesel at high pressures (typically 23,000 to 29,000 PSI).

This improves fuel atomization and combustion, increasing engine efficiency while simultaneously reducing pollutant emissions.

Tier 5 Standards

Tier 5 standards are currently under development and are expected to be implemented starting in 2025 and in the following years. These regulations aim to further reduce air pollutant emissions from diesel engines.

Key elements of Tier 5 standards include:

50% reduction in PM emissions compared to Tier 4.

30% reduction in NOx emissions compared to Tier 4.

20% reduction in NMHC emissions compared to Tier 4.

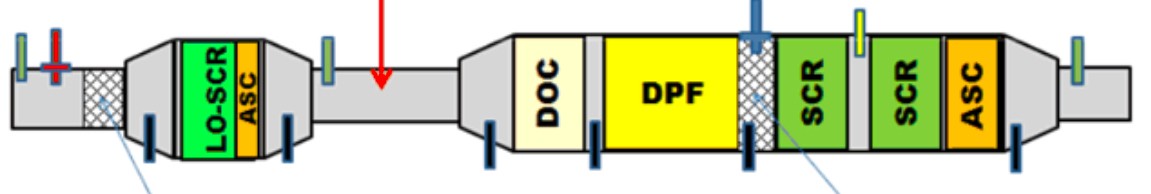

Tier 5 diesel emission control systems build upon the technologies used in Tier 4 but incorporate improvements to achieve even lower emission levels. The main components and their enhancements include:

High-Efficiency Diesel Particulate Filters (DPF+ or HPDPF)

DPF+ filters are upgraded versions of DPFs designed to capture even finer particles, as small as 10 nanometers.

Enhanced Selective Catalytic Reduction Systems (SCR+ or HPSCR)

SCR+ systems use improved catalysts for even greater NOx reduction efficiency

These catalysts further optimize the conversion of NOx into nitrogen (N₂) and water (H₂O).

Ultra-High-Pressure Fuel Injection Systems

These fuel injection systems operate at 26,000 to 32,000 PSI or higher.

This technology further enhances engine efficiency and significantly reduces air pollutant emissions.

Pros and Cons of Tier 4 and Tier 5 Diesel Emission Control Systems

Advantages

Significant reduction in air pollutants (PM, NOx, and NMHC).

Improved air quality and public health benefits.

Compliance with strict environmental standards such as those set by the EPA.

Disadvantages

High costs – Tier 4 and Tier 5 systems are more expensive than older technologies, increasing the overall cost of vehicles and equipment.

Technical complexity – These advanced emission control systems require frequent maintenance and specialized repairs, leading to higher upkeep costs.

Applications of Tier 4 and Tier 5 Emission Control Systems

Heavy-duty vehicles, trucks, and buses.

Construction equipment such as excavators, loaders, and bulldozers. Agricultural machinery including tractors and harvesters.

Conclusion

The Tier 4 and Tier 5 standards mark significant progress in reducing air pollutant emissions from diesel engines. The technological advancements developed to meet these standards have not only improved engine efficiency but have also greatly reduced their environmental impact.

To maintain performance and reliability, it is crucial to properly service these systems using specialized products and maintenance techniques. Additionally, the use of diesel fuel additives can enhance combustion, resulting in improved performance, fuel savings, and lower maintenance costs for vehicle fleets.

With the right approach, these emission control technologies will ensure long-term sustainability while helping businesses meet evolving environmental regulations.

En

En  Fr

Fr